|

Thai Stationary Steam's Last Hurrah |

|

|

Click here for an introduction to stationary steam in Thailand's rice mills. Click here for a brand new unused 21st century stationary steam engine. Click here for examples of machines in mills. Click here for one of my favourite mills in detail (2006 visit). Click here for more 21st century stationary steam engines in Thailand (2006 visit). At first sight, it's an ecological no brainer for the Thai rice mill owner. Should you burn the waste husks in your own boiler to raise steam to power your existing stationary steam engine, thereby fixing your energy costs? Or sell them as a low energy lightweight fuel for a distant power station, get an electric motor and buy back the electricity, never mind that they will be carried by some fuel hungry diesel truck which will pound the road to pieces and you will have to depend on the continuance of discounted electricity at off-peak times? And if true market forces were allowed free reign, it probably might be. The (current) government sees it differently and maybe the key is the relative thermal inefficiency of mill steam power against a power station which will offset burning the fossil fuel in transporting the husks. Anyway, as in many countries, electricity generated from biomass carries a price premium and allegedly cast iron 25 year contracts are in place for the new stations. Throw in the supposed air pollution from the chimney's smoke, the shortage of skilled labour and water in some areas and steam is in trouble. So all over Thailand, rice mill owners are opting for the convenience of electrical power and sitting back while the trucks queue up for their husks and the cash pours in. The wise ones, of course, are carefully conserving their engines against a shift in policy. In Surin, for instance, we found that less than one third of the mills which used stationary steam 3 or 4 years ago are still working that way in early 2006 and, from what we were told, the proportion will soon get even smaller. In Khon Kaen there is not a single steam engine left at work. Not far away, though, there is one mill which will probably stick with steam for rather longer than most.... While browsing the internet, I came across a single small picture of what was clearly a most unusual engine for this country. This I had to follow up and in due course Khon Kaen University lecturer Chanoknun Sookkumnerd kindly arranged for us to see it. That's right, it's a triple horizontal tandem compound engine.

It's 20 years old, apparently one of nine similar engines (variously single, double and triple) built by Poon Pon Perm around 20 years ago. Just how many others are still active, I don't know:

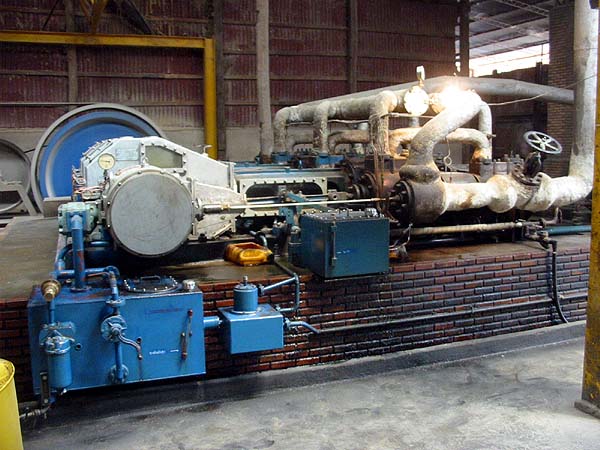

The mill owner said that the technology was basically German, but the makers were no longer in business. The three cylinders (the high pressure ones are about 9") are set at 120º to each other and this means that the machine runs incredibly smoothly even at a speed which is about double that of other mill engines which are basically local copies of relatively inefficient 19th century designs. Hence the pulley wheel is much smaller than seen elsewhere to produce a normal revolutionary speed on the main mill shaft. No Pickering type governor here, it is buried in the round silver box and connected to the regulator on the right by the rod...

The blue boxes in the foreground above are for the lubrication system which is powered off the valve gear for the first cylinder:

Consequently, the valve gear for the second and third cylinders is simpler; behind is the belt driven water pump which owes very little to 20th century technology.

This is the view in the opposite direction, note that almost all moving parts are encased which conserves oil, the whole system is remarkably leak free of steam and only a trace of oil was running out.

Most engines have a single condenser, this has two which the mill owner correctly described as 'heat exchangers'. Behind is the boiler which appears to be typical.

Finally a couple of general views:

And what is that lurking in the foreground? It's an old Ruston and Hornsby diesel engine, the sort which we have seen butchered into a steam engine at several mills. The steam engine is so reliable that it doesn't even merit standby status. |